CLUB AFIROC is renowned for the quality of its French manufacturers, who specialize in various fields, enabling interior designers to offer their clients custom-made furniture and large-scale production runs.

From wood to multi-material assembly

Some interior designers can boast a prestigious history dating back to the 19th century, creating stylish furniture since the time of Napoleon III or fittings for luxury ocean liners such as the S.S. Normandie. Times change, but the expertise has been preserved thanks to the CLUB AFIROC association

Manufacturers have master craftspeople and cabinetmakers on their teams who perpetuate the ancestral techniques of woodworking, enabling them to create bespoke pieces for luxury projects. The materials and wood varieties are endless, used in solid wood, veneer or laminate, and the finishes are custom-made (limed, lacquered, varnished, stained, patinated, sanded oak, coated), including new eco-designed creations

Other teams of carpenters handle small or large-scale furniture production to meet the needs of all types of interior design projects.

Manufacturers incorporate numerous multi-material elements such as metal, stainless steel, glass, mirrors, ceramics, composite materials, locksmithing, sheathing, and even electrical or fiber optic installations. When certain projects require specialized expertise, designers call on trusted partners who are recognized in their field.

The link between the technical design office and the expertise of the manufacturing workshops ensures that functional objectives and the aesthetics of the specifications are met, as well as deadlines and the expected level of quality.

ATELIERS DE POUILLY

Located in the Rhône-Alpes region, ATELIERS DE POUILLY draws on its history and the expertise of its master carpenters to offer “Made in France” bespoke furniture. Originally founded in 1954 in Pouilly-sous-Charlieu (Loire), ATELIERS DE POUILLY historically developed its craftsmanship in wood architectural joinery. Since 2023, now based in Le Coteau near Roanne, the company has evolved its skills to meet all interior fit-out requirements.

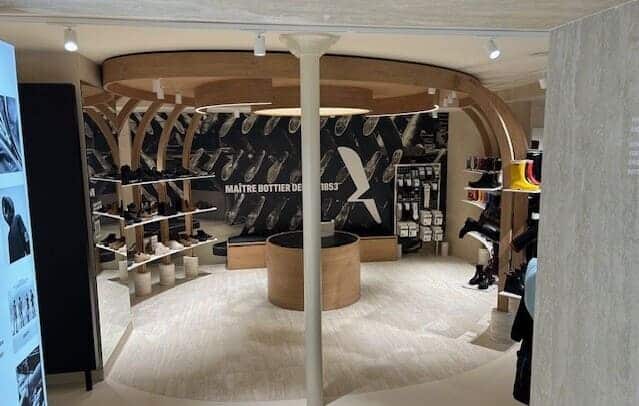

LAUGÈRE TRADITIONS

A leading specialist in fine cabinetry for 40 years, LAUGERE TRADITIONS has diversified into working with various materials to create high-end furniture for both professionals and private individuals. Originally specialized in luxury furniture for private clients, LAUGERE TRADITIONS later expanded its services to the professional sector. A new momentum is now underway to grow its client base and extend its expertise to other partners, particularly for luxury boutiques and high-end residential projects.

SOTOMOB

At the heart of the Centre-Val de Loire region, SOTOMOB offers bespoke fit-out solutions for professionals, ranging from design and engineering to manufacturing and installation. Since its creation in the late 70s, SOTOMOB—based in Aubigny-sur-Nère, France—has specialized in manufacturing furniture, fit-out elements, and heavy-duty POS (Point of Sale) displays for professionals, including retail brands, fit-out contractors, offices, libraries, reception areas, and public institutions.

TRANSFORM

Relying on years of rich expertise in woodworking, TRANSFORM has successfully diversified by offering its skills in multi-material furniture fit-outs for both public and private markets. Originally a wood specialist, the company has maintained perfect mastery and a particular passion for projects that challenge its woodworking skills. Its expertise has expanded over time to include the use of multiple materials. Thanks to this cross-disciplinary approach, the company can meet the needs of both public and private contracts.

Metal experts

Two manufacturers from CLUB AFIROC offer specific expertise

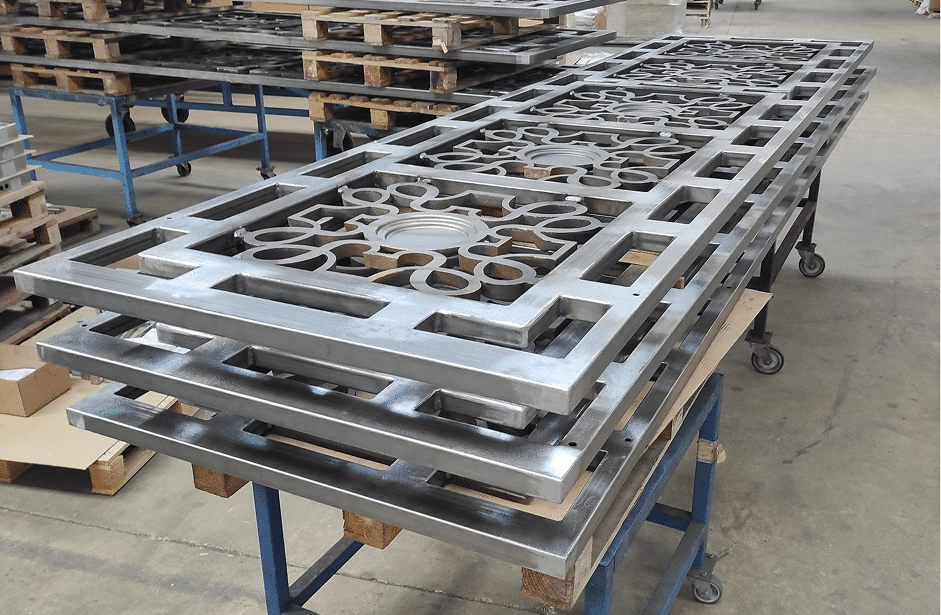

C.METAL

C. METAL specializes in the manufacture of fine sheet metal parts and locksmithing for single pieces or small and medium-sized production runs. The metals used are stainless steel, aluminum and epoxy-coated steel. The workshop carries out numerous projects involving various processes, such as laser cutting of sheet metal and tubes, bending, profile work, MIG, MAG and TIG welding, grinding and weld sanding. A unique integration service is offered to integrate mechanical, electrical or hydraulic parts.

GEORGES INDUSTRIE

GEORGES INDUSTRIE is renowned for its expertise in industrial sheet metal work and watertight partitions. The 10,000-m² workshop collaborates with numerous sectors seeking technical products that meet strict safety, watertightness and acoustic standards. It manufactures all types of fine sheet metal, mechanical and mechanically welded assemblies and meets subcontracting needs for sheet metal work (steel, stainless steel, aluminum, electro-galvanized).

Equipment and manufacturing process

Manufacturers combine rare craftsmanship and expertise with mastery of innovative materials and the latest generation of digital techniques and tools.

Depending on their configurations, manufacturers are equipped with:

- A design office, made up of experienced woodworking professionals who model furniture in 3D (using Topsolid software) and create realistic renderings to help validate the project plans. The design office technicians produce the manufacturing plans, which are then used to launch production.

- Some manufacturers are equipped with 3D CAD software interfaced with production tools. This CAD/CAM (computer-aided design and manufacturing) process optimizes and improves the reliability of machining operations right from the stage of drawing up the plans for manufacturing the fitted furniture.

- A machining center offering single-unit or mass production with edge banding and assembly, fitting and multi-material integration: metal, glass, display cases, mirrors, hardware, lighting or electrical systems, etc.

- For sheet metal work, state-of-the-art equipment includes numerically controlled punching machines, laser cutting machines, numerically controlled bending machines, rolling machines, shears and deburring machines. A digital vertical machining center has also been set up with a CN3 lathe, metrology marble and 3D control equipment.

- For clean rooms, the workshop handles all mechanical welding, bending and punching operations using digital control, as well as industrial painting. Its machine park is equipped with a high-performance CAPM system with real-time production monitoring.

- Some companies have invested in a fleet of machines with automatic wood panel storage.

- A finishing workshop with a wide range of colors and types of varnish (matt/gloss or frosted finishes), applied to all types of surfaces (lacquered, raw or fine woods). Some finishing workshops are able to replicate any type of sample: melamine, lacquer, ink, rubber effect or any other material.

- Areas dedicated to logistics (storage, packaging, order preparation, dispatch).