Located in the North of France, in Amiens, the GEORGES INDUSTRIE workshop is a specialist in precision sheet metal, serving the needs of various sectors: industry, tertiary and retail.

The company

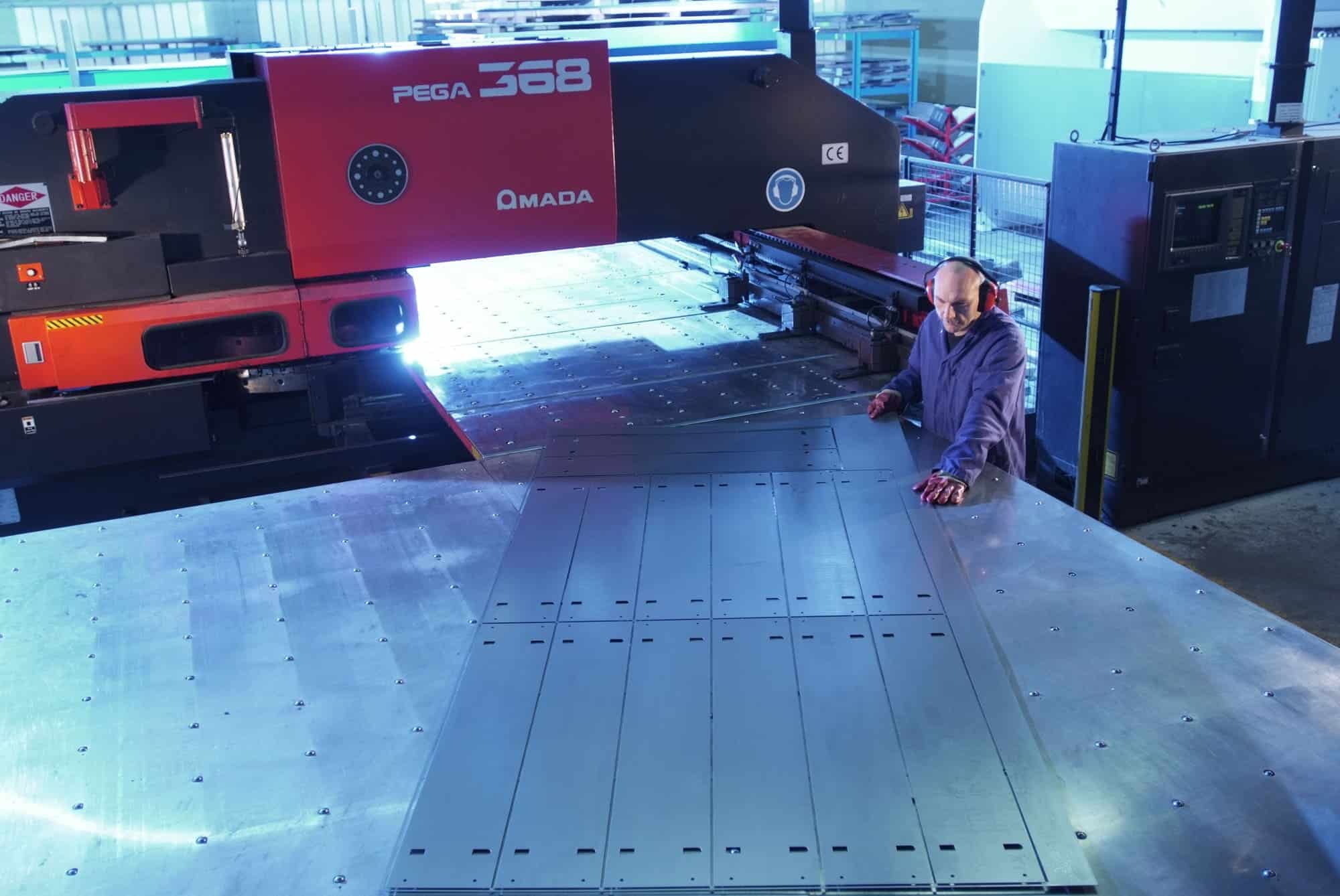

Since 1961, GEORGES INDUSTRIE has been recognized for its expertise in industrial precision sheet metal and airtight partitions. The 10,000-m² workshop collaborates with many sectors seeking technical products that meet strict standards in safety, airtightness and acoustics. The company is a key player in CNC bending and punching, welded assembly and industrial painting, offering high-level technical expertise.

Know-how

With its production unit based in Amiens, which focuses on precision sheet metal, GEORGES INDUSTRIE produces all types of sheet metal, mechanical and welded assemblies, and responds to subcontracting needs for sheet metal work (steel, stainless steel, aluminum, electro-galvanized).

Specialized in partition production, the workshop masters all operations in welded assembly, CNC bending and punching, and industrial painting.

Its machine park has been completely renovated. It is equipped with a new ERP system with real-time production monitoring that is highly complete and modern. It allows reliable handling of industrial subcontracting projects, both in lead time and quality.

The machine park includes, among others:

- Shearing stations: RAS 4 m shear (CNC)

- Punching line: AMADA AE2610NT (4000 x 1500) and AMADA 368 PEGA (4000 x 1500)

- Bending line: 2 COLLY press brakes from 3 to 4 m (CNC), one LVD press brake 4 m PPEC-5 170 tons, one RAS XLTBend 4 m panel bender

- Welding stations: ARO spot welders (fixed/mobile), SAF – TIG – MIG stations

- Complete paint line accommodating large parts, regardless of the paint application type. The paint workshop handles all RAL shades with anti-corrosion treatment, and 26 KW infrared radiant panels enable ultra-fast drying time.

Company’s strengths

- Technical capabilities meeting strict standards in safety, airtightness and acoustics

- Production capacity for small and large format precision sheet metal up to 3 meters long

- Fully internal production: design, engineering, drawings, manufacturing and storage

- Entirely made in France

In terms of CSR, GEORGES INDUSTRIE has implemented waste sorting bins and collaborates with recycling companies such as Veolia.

The company has fully updated its machine park to optimize employee safety and bolster productivity.

Clients and products

GEORGES INDUSTRIE works for a wide range of sectors, producing sub-assemblies and assemblies for manufacturers of packaging and wrapping machinery, the nautical industry, industrial construction, clean rooms, office furniture, agricultural and railway equipment, catering and retail.

The products are mainly partitions, ceilings, doors and accessories (lighting fixtures, for example) that have to meet geometric and ergonomic requirements, as well as performance criteria that fulfill specific needs for watertightness, cleaning and decontamination, thermal insulation, acoustic insulation or fire resistance.

Examples of particularly technical products include:

- Technical partitions

- Sliding doors

- Airtight cold room doors

- Walkable technical ceilings

- Stainless steel carts

- Monobloc pass-throughs with electromagnetic locking

- Decontamination air showers

- Maintenance hatches with EDF-type locks

- Oven inspection hatches with tinted windows

- Displays, shelving and POS displays for stores